First published in Flight Levels Online, Spring 2013 issue

Twin Commander Aircraft has developed a Custom Kit that addresses wear in a main landing gear clamshell door bearing, and has issued a Maintenance Alert for proper installation of replacement trim cables.

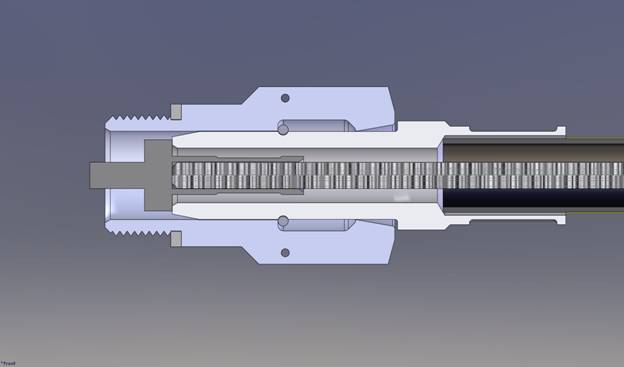

Custom Kit 187 grew out of reports that the front bearing in the main landing gear clamshell door mechanism wears over time. This wear causes excessive play and gaps between the two clamshell doors, resulting in additional vibration and aerodynamic drag. This excessive gap also may contribute to cracking of the nacelle aft bulkhead.

The original-installation front bearing in the clamshell door mechanism is made of aluminum bronze alloy, and essentially is a straight bushing. Due to the complex angle of the torque shaft, it is not uncommon that both shaft and bushing were installed pre-stressed, thus further accelerating bearing wear.

Twin Commander Aircraft developed a new torque shaft design that incorporates a ball-type swivel bearing. This bearing is made of stainless steel and is able to compensate for any installation misalignment.

Front bearing on clamshell door torque shaft can wear over time, leading to gapping of the doors.

Custom Kit 187 uses existing aircraft parts, including the most expensive weldment, to reduce the price of the replacement. The original shaft is shortened by cutting off the worn-out portion, and then adding an extension to the shaft. The extension is precision manufactured to ensure proper shaft/bearing fit. The kit includes the bearing, bearing housing, shaft extension, and hardware.

Models affected include the 680W/T/V and 681, the 690/A/B/C/D, and 695/A/B.

The Maintenance Alert was issued as a result of receiving warranty clams from authorized Services Centers having to do with trim cable installation issues. Specifically, the snap ring that retains the cable connecting nut was consistently breaking during the installation process.

After extensive research Twin Commander concluded that there was no problem with the cable design or manufacturing quality. Instead, the problem was traced to the design of the cable end. It was obstructing the tongue-and-groove-type engagement with the trim system actuator. This was evident in tight, hard-to-see compartments.

The Maintenance Alert serves as an immediate corrective action. It explains the problem and the solution for Twin Commander technicians, and alerts them on what to watch for when installing replacement trim cables.

Most piston- and turboprop-powered Twin Commanders are affected by the Maintenance Alert.

Twin Commander also worked with vendors on a new trim cable with a sliding outer nut. This design feature increases the thickness of the snap ring, and improves the visibility of the tongue so that technicians can verify proper engagement prior to the final torquing of the nut.

The new-design cables are available now at authorized Twin Commander Service Centers.

For more information on CK 187 and the trim cable Maintenance Alert, conduct your authorized Twin Commander Service Center.