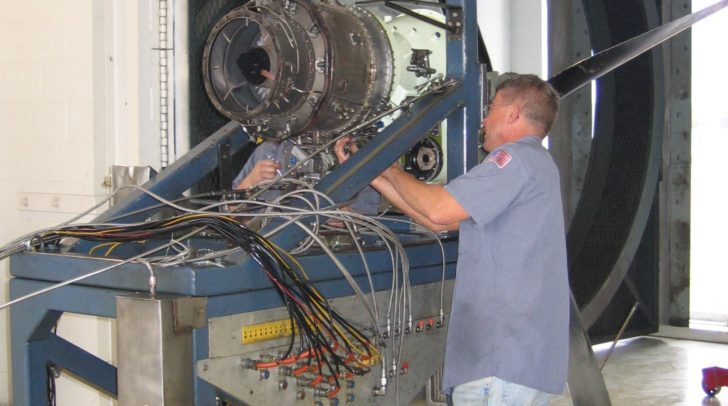

As the head of National Flight Service’s turbine shop, Mike Bell knows the Honeywell TPE331 intimately. When you work for a company that sees dozens of engines a year for repair, inspection, and overhaul, certain patterns begin to emerge.

Bell said that the TPE331 is an incredibly reliable and durable engine, and that operators can do a few simple things to bring down their scheduled maintenance costs. He offered a few tips to help avoid problems on starts. “You’ll get away with a cheap hot section if you follow most of these rules,” he said.

- Pull the prop. Take the time to pull the propellers through for about 15 seconds before starting the engine, Bell said. This quick and simple step ensures nothing is in the inlet, including the cover. Don’t laugh. It’s happened.

- Use ground power. “Everyone thinks their batteries are top notch.” He gets a call about once a month from someone have starting issues. The first piece of advice is to try ground power for the start. Usually that fixes the issues. Bell counsels all his customers to use ground power whenever they can. It’s less strain on the engine, and helps to avoid hung starts, the real power killer.

- Avoid hung starts. This piece of advice might seem obvious. After all, avoiding hung starts is day one of turbine transition training. Yet, Bell estimates that more than half the engines in his shop for overhaul have experienced a hung start, and many have markers of multiple hung starts.

The first step in avoiding the problem is being able to recognize it. The critical rpm range is between 18 and 28 percent, where the engine should be accelerating at about 1 percent per second. Anything less than that and damage can occur.

Hung starts have a few causes, including the previously mentioned battery issues, as well as not enough fuel being delivered. When this happens the second impeller makes contact with the compressor housing resulting in opening up the compressor clearances. Since this is where a lot of the TPE331’s power comes from, it can result in permanent power loss. But the problem can also be insidious. Although power losses may be immediate, it’s also possible it won’t be noticeable until much later, causing the diminishment of power prematurely. Bell said it’s easy to tell on the compressor housing how many times the start was hung up because each bit of contact will be a different color, indicating different lapses in time.

We count on our engines to be the most trustworthy and reliable components in the airplane’s many systems, and with a little attention and care that’s exactly what they will be.